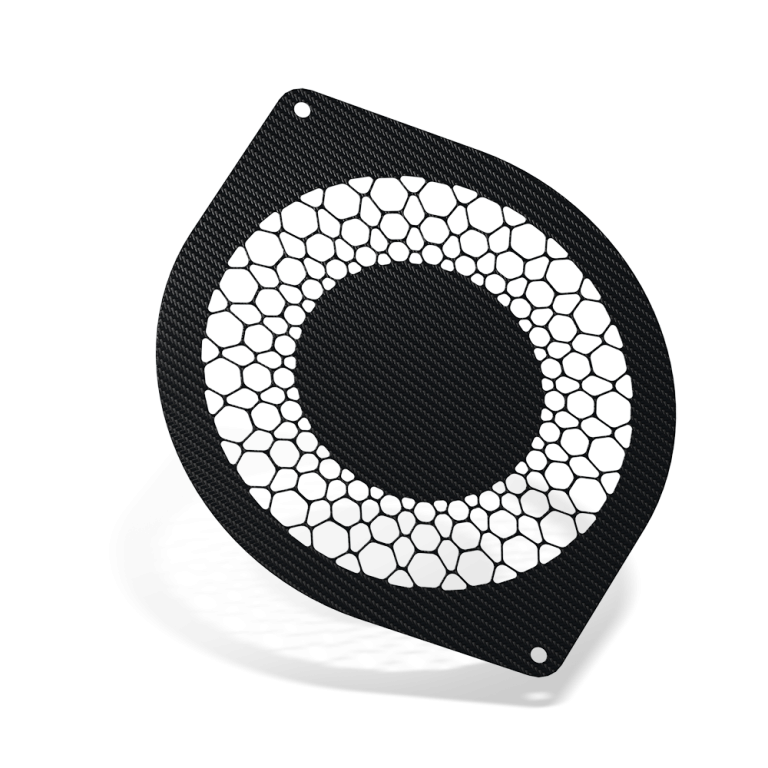

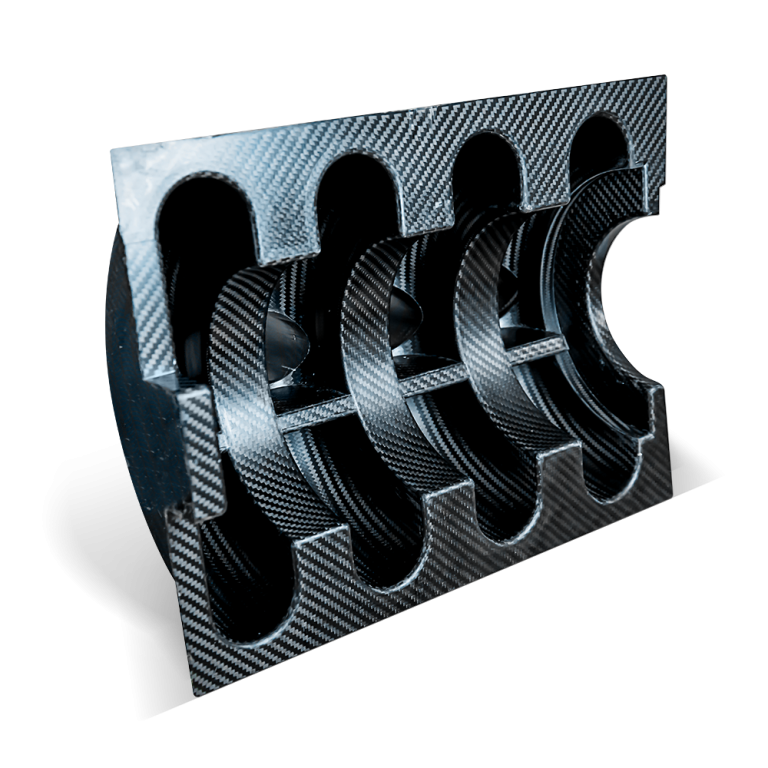

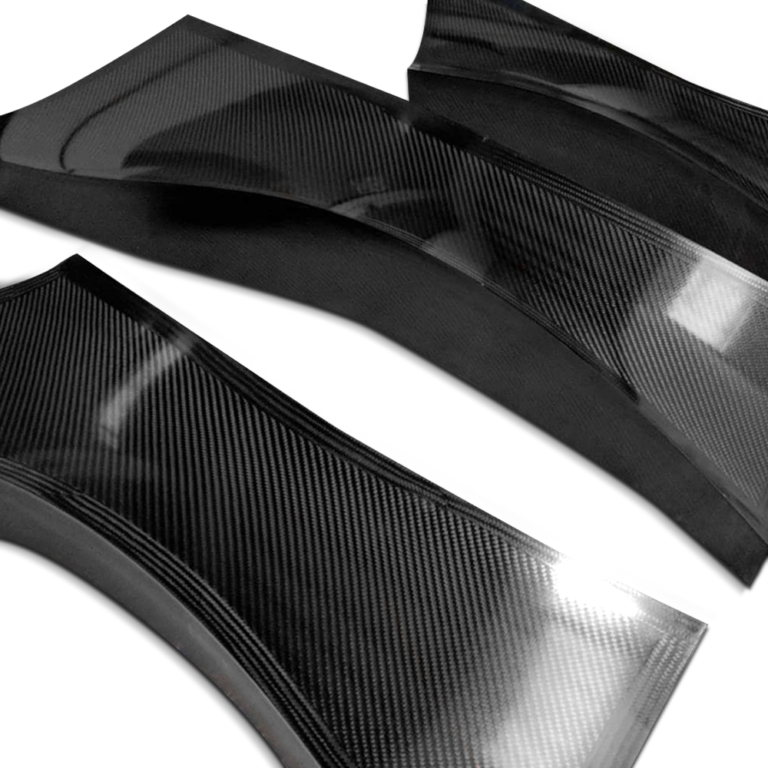

Each single process of our machining is carried out with meticulous attention.

The world of composite materials and engineering materials is very broad. Scientific research and technical development are always in great ferment in Libe and move with the common goal of constantly improving the aesthetics of our productions without neglecting the artisan aspect of the process.

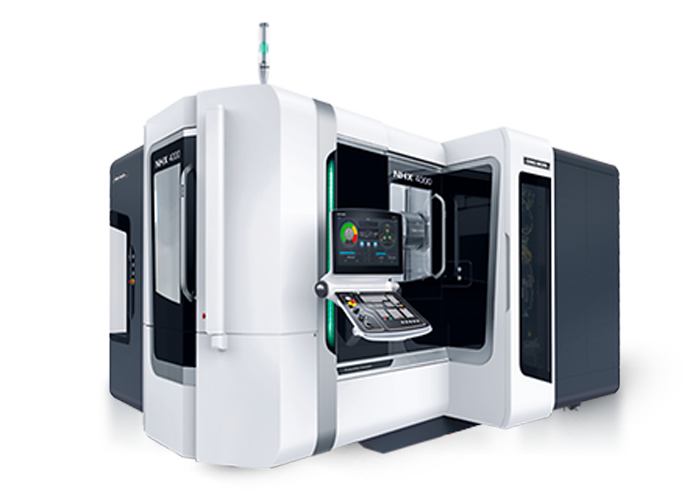

Thanks to the available technology, this process can be divided into:

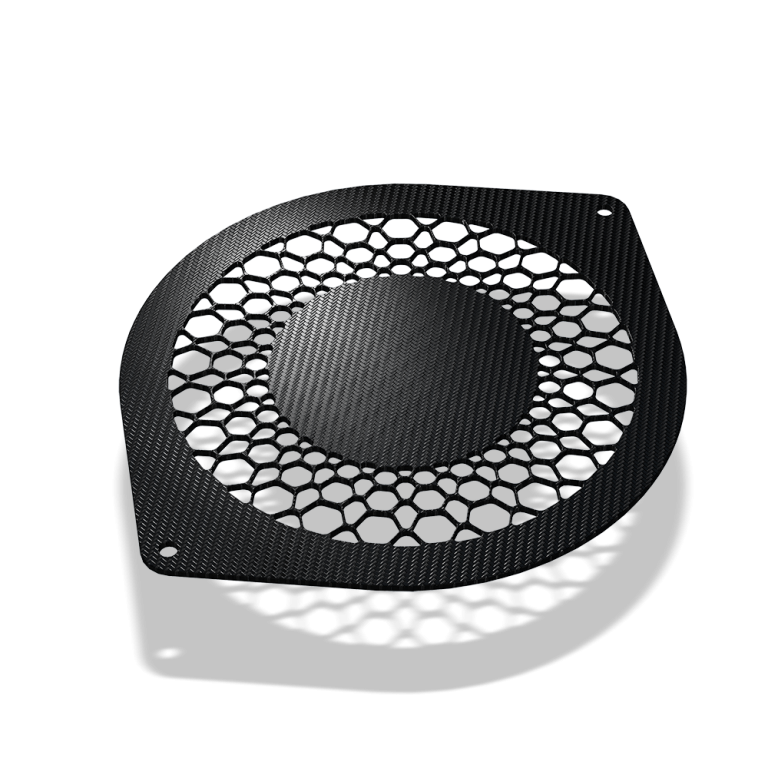

• CNC Machining

• Laser Cut

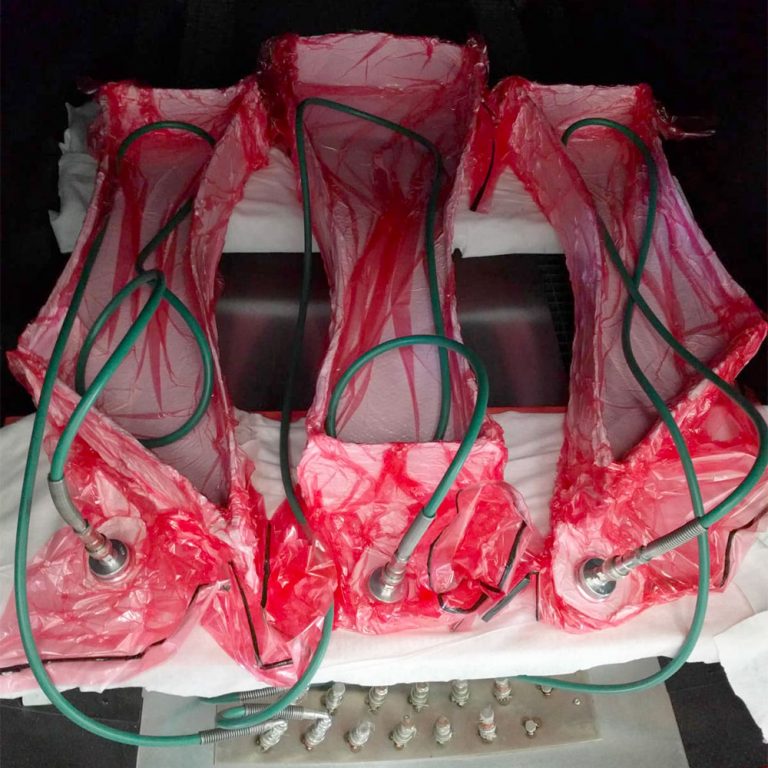

• Mold and Counter Mold

• Autoclave