Ayrton Senna

Brazilian Racing Driver

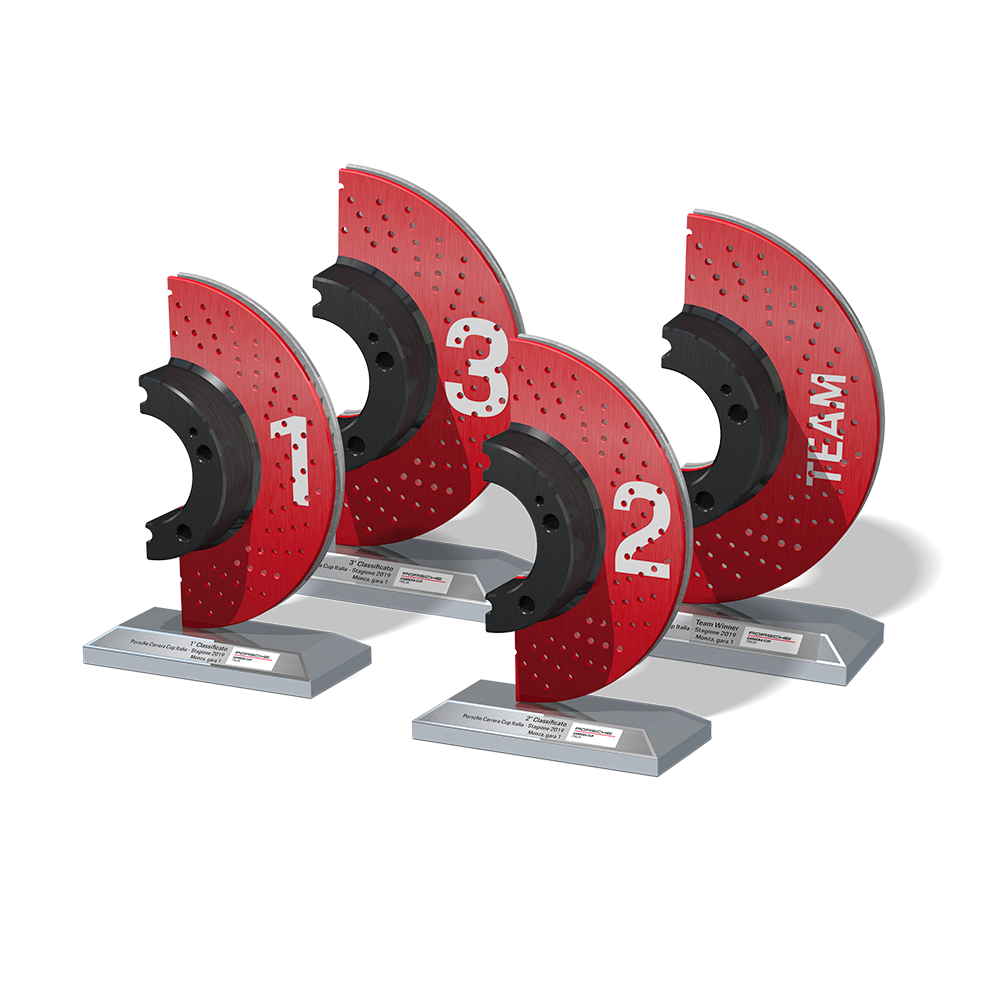

Following a solid clientele acquired on the national territory, Libe has been looking for growing also in the foreign markets in recent years. The world of awards is one of the main sectors where Libe is certainly able to operate on an international level with satisfaction similar if not superior, to the one deriving from the domestic market. Libe stands out from its international competitors thanks to the special creations (more and more customized trophies) through which it is possible to better highlight the brand of the promoter of the competition. Motorsport is certainly, also out of its passion for it, where Libe finds its maximum expression by supplying products to many companies, from the Karting sector to the promoters of endurance races.

Carbon Fiber Trophies

We manufacture design trophies by combining the elegance of metal with the sportiness of carbon fiber. Each metal detail is completely CNC machined, subsequently oxidized in multiple color variations and customized using direct UV LED printing systems with the application of a primer for adhesion to the surface. The decorative or structural element in carbon fiber can be made with various types of processing, from the most complex in the Autoclave by creating OK molds or by milling on CNC mini-centers.

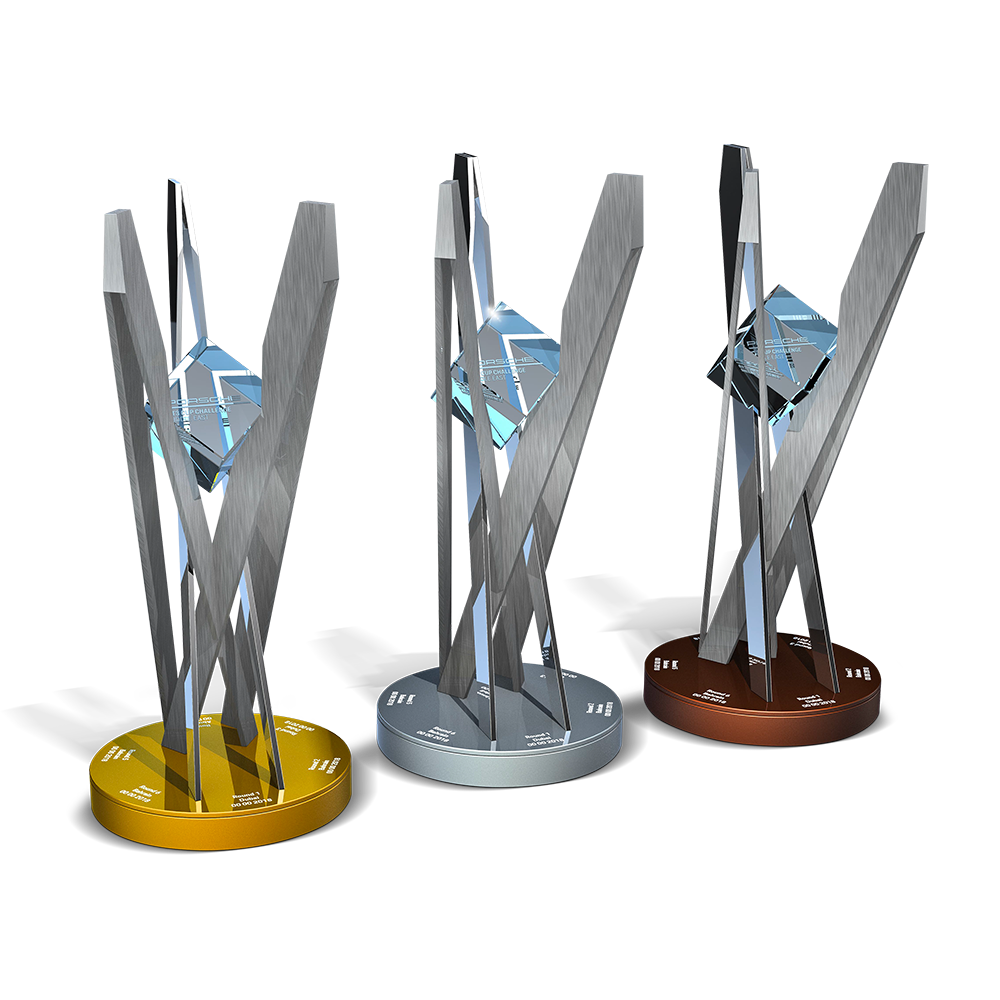

Custom Trophies

Trophiesmade in aluminum and carbon fiber. The base is obtained directly from the billet by CNC milling, starting from a round 300mm diameter 80mm thickness in 11S Aluminum. The processing also includes the drilling cycle, necessary for fixing the central support. The central portion, obtained by CNC milling from T6082 Anticorodal Aluminum sheet, satin-finished with two passes of sanding (roughing with 120 and 280 grits, to then be finished with scotch breil) after the mechanical processing, before undergoing a treatment of anodic oxidation in the three brill colors (gold, silver, bronze).

Externally, three shaped twill finish carbon fiber covers are anchored to the central structure by means of three mechanically worked 3D ribs.

The three covers are made with two particularities, the internal part in a glossy finish since the counter mold is mirror polished after the mechanical processing, while the outside in a matte finish on which, after painting with an opaque transparent epoxy, is printed resuming the trophy colors in pad printing with all the shapes of the circuits and the dates on which the races are hosted.

The trophy has a total height of 1m, width 300mm, total weight 4.75 kg (complying with the FIA tolerances which is 5 kg).

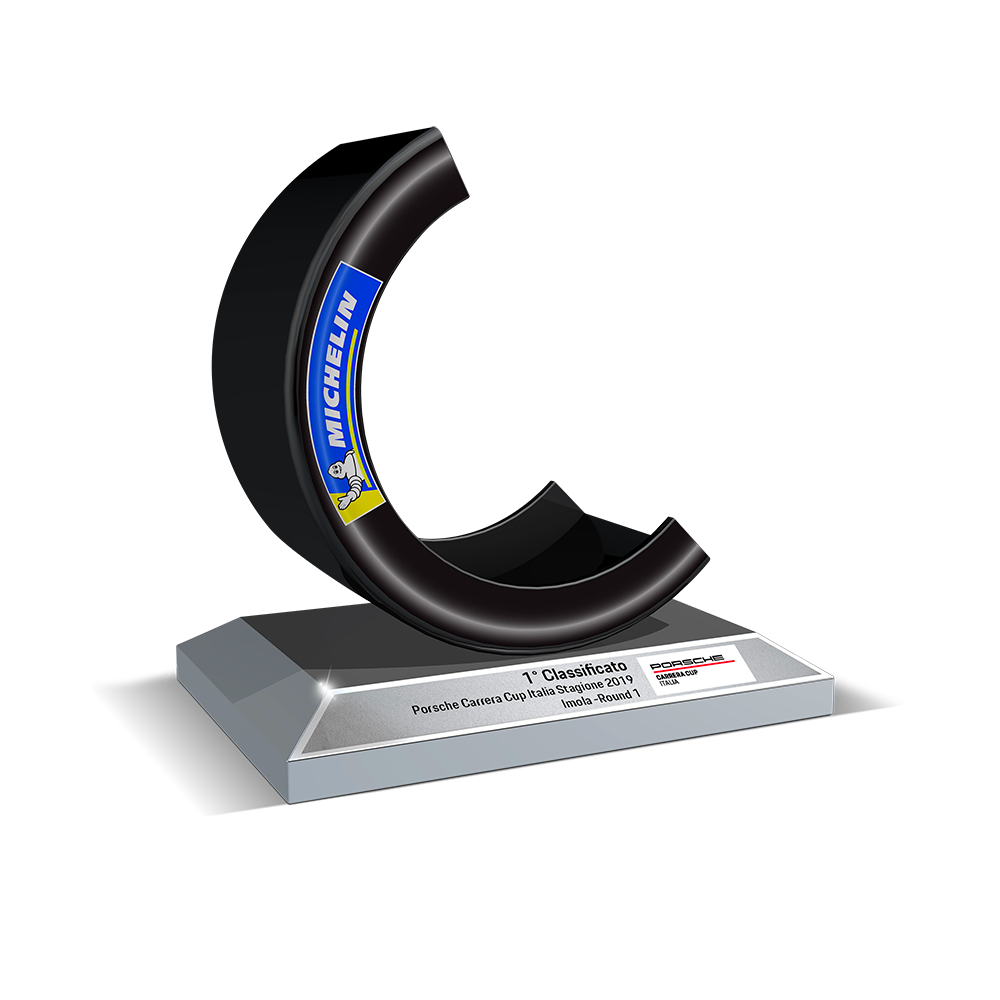

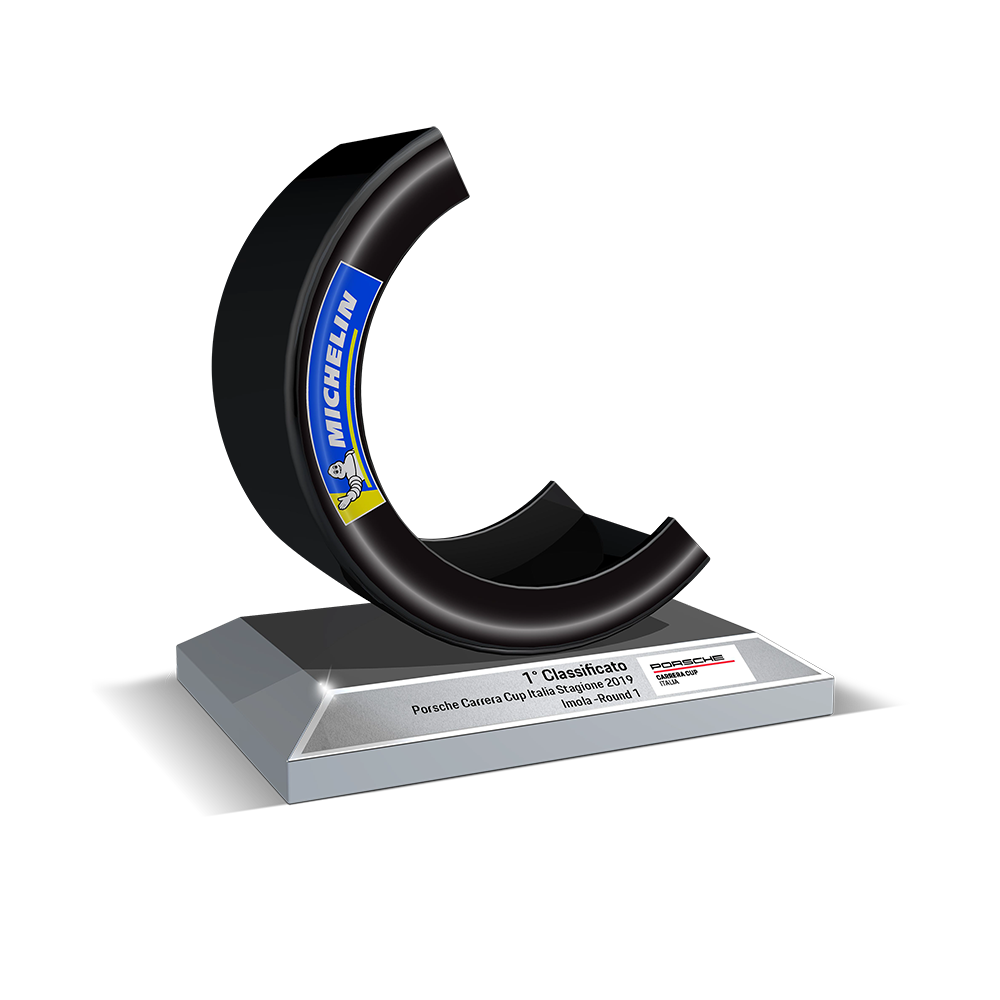

Metal Trophies

The manufacturing of metal trophies is certainly one of the oldest processes in the history of Libe. We have made important developments in this area over the years. Improved mechanical machining on metal and machining with the third interpolated axis when the budget allows, thus offering a product in three dimensions.

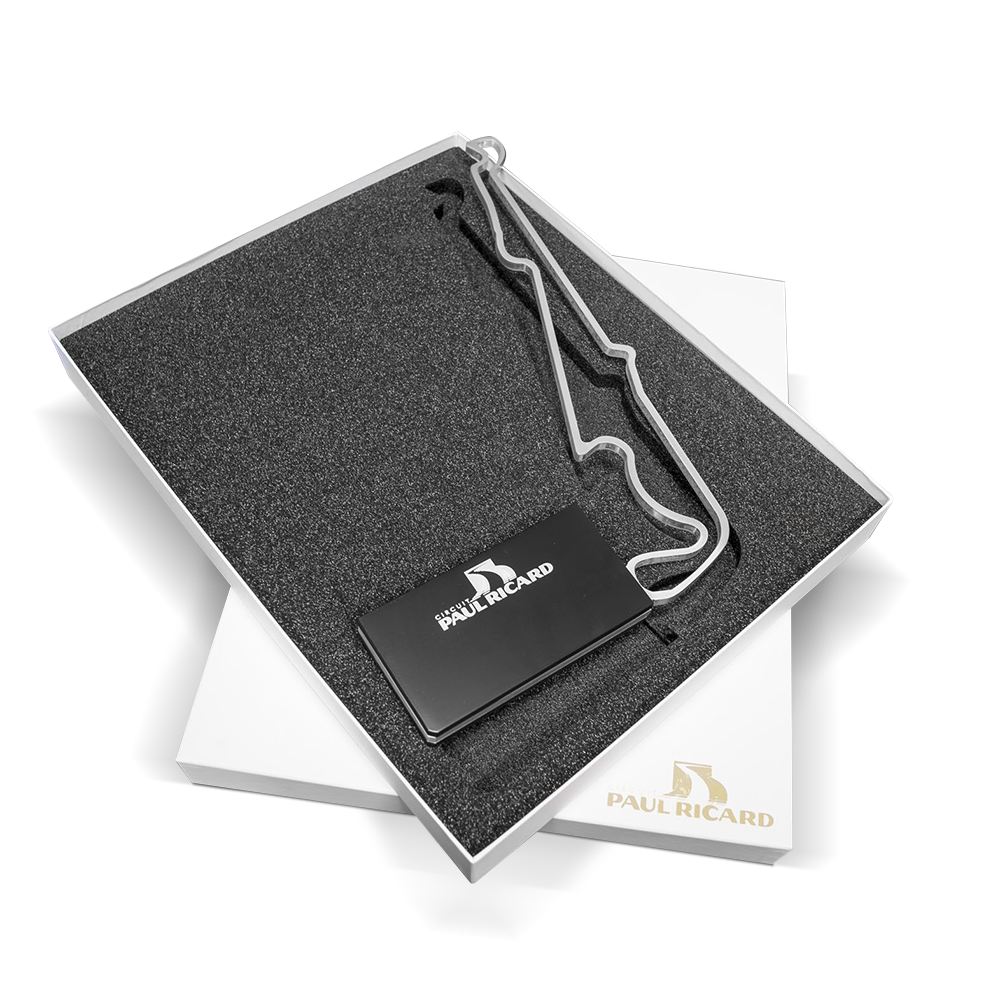

Plexiglass Trophies

The same processes that Libe applies to metal are extended as well to product entirely made of Plexiglass. Each mechanically worked detail undergoes polishing, satin finishing and sandblasting treatments, all managed entirely inside Libe in order to be able to classify a Made in Libe product.

Standard Cups

Not simple Cups, but a classic product of extreme quality. Libe offers a wide range of products, at the Customer’s preference. All products in our catalogue are manufactured by skilled craftsmen out of noble materials, such as brass in a galvanic bath silvered in 1000 or 24K gold.

Cups with a refined design in materials and finishes with excellent quality / price ratio: laser-cut metal products, printed and metallized cups. The Customers Libe daily supplies are increasingly international; we export our products to various European countries (Germany, Austria, Spain, France, Belgium, England, Portugal…), to the USA, Canada, Middle East, China, Malaysia and Singapore.

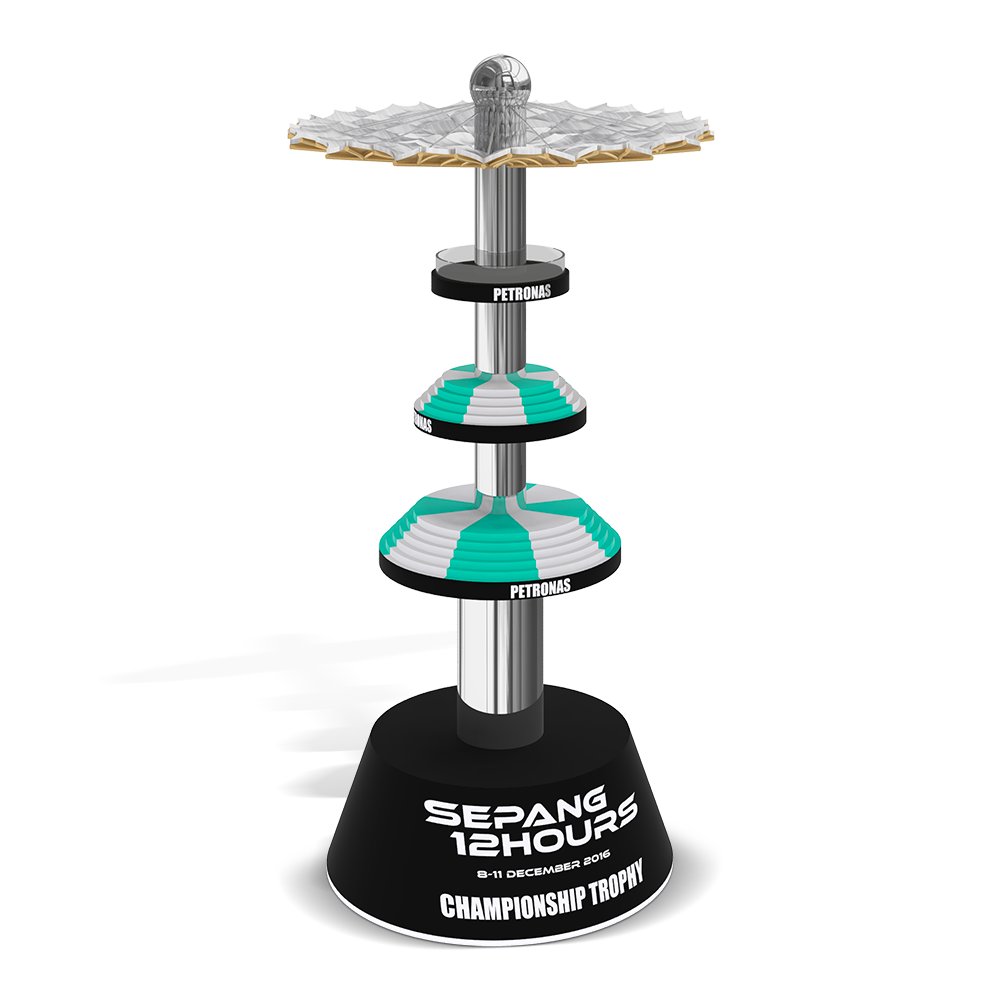

The Galà

Even in the final conclusion of each racing season, Libe is there for its Customers. We develop unique trophies dedicated to final happenings of each season, for any Customer. As demanded by the code of prestigious ceremonies, our trophies respect the proper dress code.

Coined Medals

A tradition brought into the future. The most sophisticated CAD CAM software have made possible to significantly improve the quality of the mold, drastically reducing its execution times and cancelling the need for the model maker. The medals are minted by mechanical shearing processes and subsequently treated with a galvanic bath and finalized by enameling with epoxy enamels to ensure brilliance and durability.

Podiums

At the end of a fantastic race weekend, the moment of the podium arrives, an instant that remains etched in the memory of each driver whom, forever, will relive his emotions by looking at that magic object that is the trophy he won.

Let us improve your business!

Contact us now and let us understand how we can help you improve and grow your business.